HMS Chiller

H.M.S.

CHILLER

SUPER COOL IDEA FROM TITE-SPOT

H.M.S. CHILLER

Heat Management System

CHILLER

REFRIGERATING YOUR SHOP'S COMPRESSED-AIR FOR COOLING

- USE NO EXTRA SHOP AIR

- DISSIPATES MORE HEAT FROM YOUR WELDING GUNS

- GREATER CONSISTENCY OF WELDS

controlling welding parameters gives more consistent

performance - COOLS TRANSFORMER FOR OPTIMUM PERFORMANCE

Because the chilled air enters the welding cable at the connection to the transformer, heat is pulled from the transformer. This cooling effect further stabilizes the transformer's performance!!

- WELDING ELECTRODES (WELDING TIPS) LAST LONGER

Less heat related peening of tips

Less chance of galling threads on tips - SLASH HEAT RELATED DAMAGE TO WELDING TOOLS

- COOLS THE TITE-SPOT PLIERS SO YOU CAN WORK FASTER & LONGER !

- TWO GUN OVERLAP WELDING TOOLS STAY COOLER

- LET'S DO THE MATH: TO SHOW THE QUANTITY OF THE HEAT WE MUST DISSIPATE

I2R= power lost in the welding cables that must be dissipated.

I is the current the welder is putting out ( say 4,000 amps) so

I2 equals 16,000,000, a very big number

R= the resistance of 17 feet of welding cable @ .0035 ohms

per foot = .00595 ohms, a small number

So the power to dissipate (16,000,000 x .00595) = 952,000

watts or, to put it another way, the heat of 9520 - 100 watt

light bulbs, a lot of heat

HMS Chiller

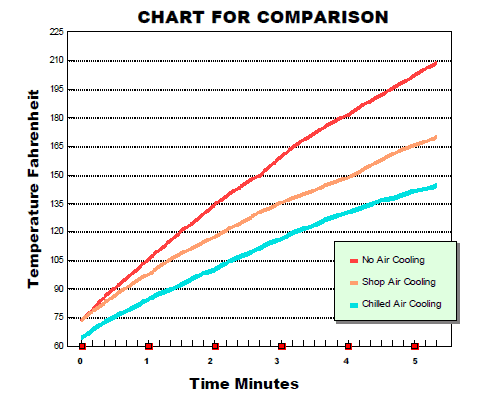

- Temperature after 1 minutes

- Temperature after 3 minutes

- Temperature after 5 minutes

Test conditions:

Select program number *(2)* ,attach

temperature probe to air out let orifice of upper jaw. Set flow of air to 6 cfm for both tests using air. Fire welder every 10 seconds Check temp after every welds.