Products

DiGi S.W.A.T.

The Heart of the DiGi S.W.A.T. Welder is the extended service transformer. This 10 volt transformer has an extended duty cycle because of its thermal mass (53 pounds of transformer laminate) BIGGER than any competitor. Oversized copper windings (6.5 pounds of #8 square wire on the primary, and 8 pounds of 1 inch by 3/8 inch bar on the secondary) minimize heat-build in heavy-duty use.

S.W.A.T. Welder

The heart of the S.W.A.T. Welder is the extended service transformer. This 10 volt transformer has an extended duty cycle because of its thermal mass (53 pounds of transformer laminate) BIGGER than any competitor. Oversized copper windings (6.5 pounds of #8 square wire on the primary, and 8 pounds of 1 inch by 3/8 inch bar on the secondary) minimize heat-build in heavy-duty use.

The TITE-SPOT PLIERS

TITE-SPOT PLIERS TMTHE TITE-SPOT Welders has a unique and patented spot welding pliers, featuring – cooling of the cables and pliers assembly using compressed air from your shop. This cooling feature improves the TITE-SPOT duty cycle over 800%. The cooling also lets the technician work without clumsy gloves, improving his productivity and generating bigger profits.

TITE-SPOT Cool Cords

SINGLE SIDED WELDING IS EASY TO DO TITE-SPOT Welders, Inc. offers you the ultimate in Two Gun spot welding. The TITE-SPOT Cool Cords provide the technician with Two-Gun Welding, One-Gun Welding, Pull Stud Welding, Heating and Shrinking. Also, see page 14 for Electric Dent Wizards.Forced air cooling is a patented Cool Cords feature.

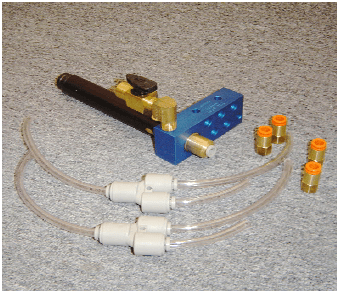

TITE-SPOT Accessories

Measure input voltage at transformer while the welder is running at maximum power. Next, using the clamp on the amp meter, measure current into transformer at maximum power. And last, measure output voltage at the transformer. Now calculate the output current; V-Iinput/Voutput = Ioutput.

HMS Chiller

Select program number *(2)* ,attach

temperature probe to air out let orifice of upper jaw. Set flow of air to 6 cfm for both tests using air. Fire welder every 10 seconds Check temp after every welds.

Technical Info

Resistance Spot Welding is the joining of overlapping pieces of metal by applying pressure and electrical current. These joints created by resistance spot welding form a “button” or “fused nugget.”