Single-Sided Spot Welders for Single-Sided Spot Welding Applications

TiteSpot provides Single-Sided Spot Welders among a large family of spot welding equipment, often customized to best suit customer needs.

Resistance spot welding has many applications and many ways of being performed.

Resistance Welding the old-fashioned way. TiteSpot offers convenient portable Single-Sided Spot Welders and custom solutions. Photo courtesy of Kevin Wood

In short, resistance spot welding occurs when an electric current is passed between two or more layers of metal, and the layers are pushed together. This is not much different than what my great uncle Ben Ogle did in his blacksmith shop. He heated two pieces in the forge and welded them by hammering them together. He was very skilled at this, determining temperature by the color of the hot metal, adjusting the force of the hammer blows as the metal cooled while being worked.

You may have heard the term Squeeze Type Resistance Spot Welding (STRSW). This is what most people think of when Spot Welding is discussed. Two arms coming from the welding transformer pressing on pieces of sheet metal like a C-clamp that pushes the weld together as current is applied. My favorite visualization of this is a video of an automobile production line with the robots welding car bodies together. The great advantage to using this method is that you can create and control as much steady squeezing force as is required. Once the system is dialed in, the need for user skill is reduced greatly.

One of the drawbacks to STRSW is when the structure of the item to be welded gains complexity. The size, weight, and cost of the welding arms grows dramatically as reach is increased. This is where Single-Sided Spot Welders can be utilized as they can be applied in different ways.

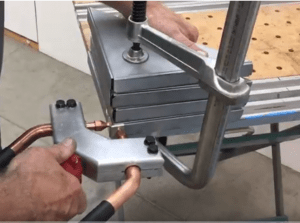

Custom Single-Sided Spot Welder saves our customer thirty minutes of production time PER PRODUCT made.

There are basically two ways to use Single-Sided Spot Welders.

1. Two welds can be applied from the same side using two guns. (See the “Spot Welding Corner” video.)

2. One weld can be applied using a single gun and surface being welded too is grounded using the other lead.

There are an almost infinite number of ways to apply SSSW. We have created dozens of custom fixtures and welding implements for customers over the years. If you have an application for which you think a Single-Sided Spot Welder may be utilized, please let us know. We are always happy to discuss new applications.